Safe Sanitation Reinvented

How the Droilet™ Works

The Functional Process

- Urine is separated and diverted

- Solid waste gets dumped into a Mixing Zone

- Solid waste and sawdust are combined to form feedstock

- Feedstock is mixed and digested by a bacteria culture

- Feedstock is transformed into Biosynthate

- Biosynthate is isolated and pasteurized

Five-step solid waste treatment process

Step One - Urine Diversion

- Urine is separated. Further processing dependent on site conditions.

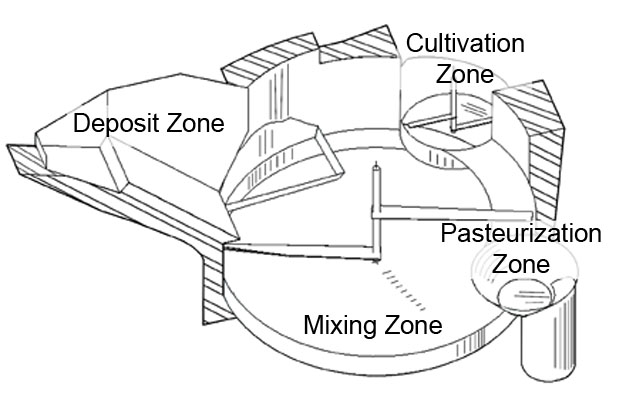

Step Two - Deposit Zone

- Solid waste is deposited on a stainless steel deposit tray called the Deposit Zone.

- A scoop of sawdust mix is added before or after the tray is dumped.

- A paper liner can be used to assist in cleanliness.

- The deposit tray dumps its contents into the Mixing Zone.

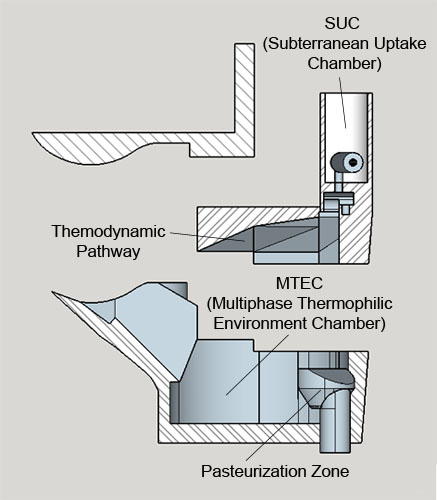

THE MTEC™ (Multiphase Thermophilic Environment Chamber)

Step Three - Mixing Zone

- The solid waste and sawdust mix is processed with an automated mixing blade to form feedstock.

- The Mixing Zone has a heating element to keep the feedstock at optimal conditions, allowing a natural bacteria culture to thrive and start feedstock aerobic digestion

- Some of the feedstock accumulates in the Germination Zone for the purpose of reseeding which keeps the process going.

- Meanwhile some of the feedstock also moves into the Cultivation Zone.

Step Four - Cultivation Zone

- The Cultivation Zone has a heating element and automated mixing blade for stage two treatment.

- In the Cultivation Zone the feedstock continues digestion and transformation into a new substance called Biosynthate. In this area the feedstock is semi-separated from the Mixing Zone.

- The newly formed Biosynthate fills up the Cultivation Zone and is moved across a bridge by a transportation blade into the final treatment area, called the Pasteurization Zone.

Step Five - Pasteurization Zone

- In the Pasteurization Zone, the newly formed Biosynthate is isolated.

- The Pasteurization Zone also has its own heating element and automated mixing blade for this final processing and treatment step.

- The Biosynthate is moved into an output tray where it is collected and emptied into a collection container.